High-quality Self-Adhesive mats or corners are used to specify a specific position. These mats allow you to adapt to a variety of tools, furniture, and things currently present. These are durable, and have sticky shapes. They are cost-effective and help to arrange workshop or floor-marking systems more concretely. These are usually in the form of visual clues such as lines, forms, and signs on floors to highlight the way is known as floor marking. These cues are used to partition spaces, highlight dangers, delineate workstations and storage areas, direct traffic, and communicate essential safety or instructional information. Floor marking is a part of a broader visual communication system that also includes signs and labels on the walls. Paint or adhesive materials, such as floor marking tape, floor signs, and floor marking shapes, are typically used to designate the floor. Tapes are available in a range of colours, materials, and thicknesses to suit your needs. You can choose tapes based on the conditions of the place you’ll be marking. These colours make it easier for staff to remember what each hue means and decrease the number of floors marking items that need to be maintained in stock. Green, blue, and/or black floor marks for equipment such as racks that contain raw materials, work in progress, or finished items should be used. The scope of these standards is quite limited. Red should be used to designate fire prevention equipment, emergency stop devices, and containers containing dangerous compounds, according to the standard. Physical dangers such as hitting, stumbling, falling, tripping, and being caught-in-between should be marked with yellow hazards.

- Safety Red: Red safety signs are used to recognize danger and put a halt to it. For example, flammable liquid containers, emergency stop buttons, and fire protection equipment.

- Safety Orange: Orange safety signs are used to highlight intermediate-level warning dangers and dangerous equipment parts. Examples include machine components that might inflict cuts, crushes, or other injuries, as well as moving elements like gears, pulleys, and chains.

- High Quality Yellow Floor Marking Tape: Physical hazards such as tripping, falling, hitting against, and being caught-in-between dangers, storage cabinets for flammable or combustible products, and containers for corrosives or other unstable compounds are all examples of yellow safety.

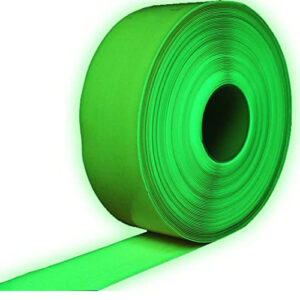

- Safety Green: These green safety signs are used to mark emergency exits, first aid stations, and safety equipment including deluge showers, gas masks, and stretchers.

- Safety Blue: Used on informational signs and bulletin boards to highlight safety information, used in the railroad industry to signify cautions against starting, using, or moving equipment that is being repaired or worked on.

- Black/Yellow: A border of black and yellow striped marking is used to surround any area or piece of equipment where workers may be accidentally exposed to a specific danger. These black and yellow borders around flammable and combustible material containers, for example, the black and yellow’s purpose. The boundary serves as a warning that extra attention should be used while entering and operating in the region.

- To identify traffic or housekeeping marks, safety black, white, and yellow, or combinations thereof, should be utilized.

Showing all 10 results

-

High Quality Photoluminescent Floor Marking Tape

£109.94 – £188.80Quick View -

High Quality Black / Yellow Floor Marking Tape

£108.94 – £188.80Quick View -

High Quality Black Floor Marking Tape

£85.94 – £145.88Quick View -

High Quality Fluorescent Floor Marking Tape

£85.94 – £145.88Quick View -

High Quality Green Floor Marking Tape

£85.94 – £145.88Quick View -

High Quality Orange Floor Marking Tape

£85.94 – £145.88Quick View -

High Quality Red and White Floor Marking Tape

£108.94 – £188.80Quick View -

High Quality Red Floor Marking Tape

£85.94 – £145.88Quick View -

High Quality White Floor Marking Tape

£85.94 – £145.88Quick View -

High Quality Yellow Floor Marking Tape

£85.94 – £145.88Quick View